Origins

SISME’s first plant opened in Olgiate Comasco (Como) on 31 January 1957, on the initiative of the US multinational Ranco.

A strong link with the region

Olgiate Comasco welcomed the new company, satisfying the far-sighted strategy of the Municipal Administration that had long called for sectoral differentiation of the production sites. The strong textile industry in the region had forced the entire local economy to follow fluctuating economic trends.

Perfect symbiosis

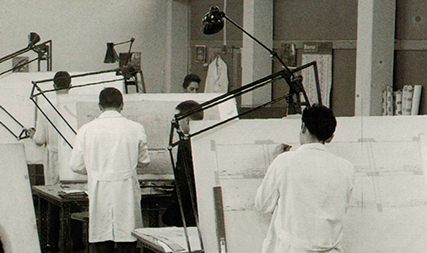

Ranco immediately benefited from the skills, abilities and industrial culture spread among the local labour force: its production process required the same skills developed in the textile industry. The contribution from qualified personnel was therefore fundamental for the company’s success from the very beginning.

CHINA

CHINA