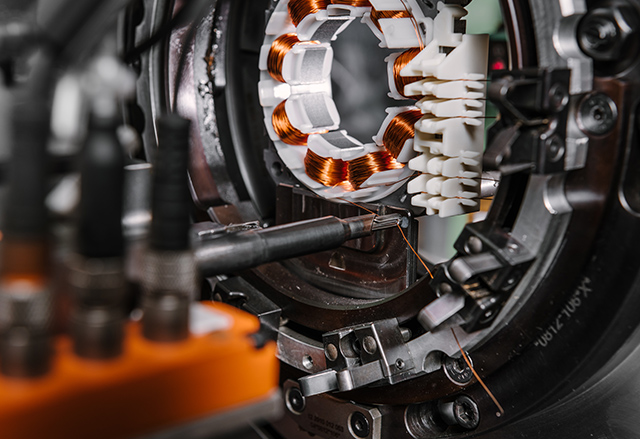

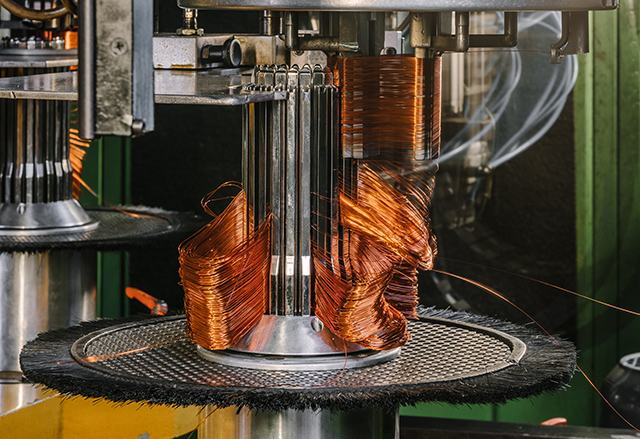

Each transformation requires specific technology to be completed: semi-finished product assembly processes or assembling finished components, processing and working on complex products and goods have become part of Sisme’s DNA over time.

Its level of technological knowledge regarding manufacturing processes allows Sisme to display its value by integrating new methods of production and organisation, fully embracing the lean production methodology and the “zero waste” philosophy.

CHINA

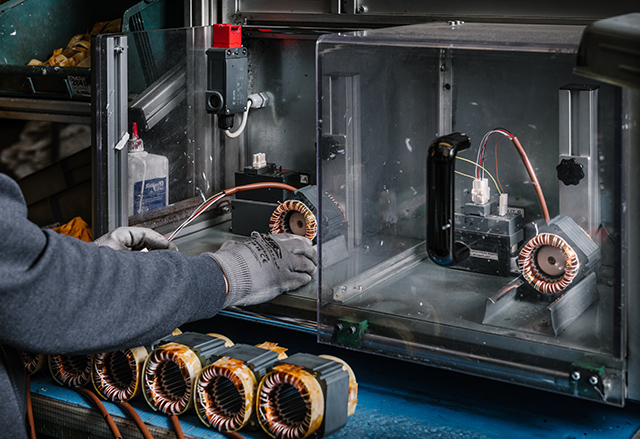

CHINA Production

Production Manual

Manual Automatic

Automatic End-of-line

End-of-line